Choosing the Right Retaining Ring for Your Application

Understanding Retaining Ring Types

The first step in selecting the ideal retaining ring is understanding the various types available, like the range of options that American Ring offers.

Tapered Section Retaining Rings

Internal tapered section retaining rings are designed for installation inside bores or housings. These rings excel at securing components like bearings or gears within a housing, providing a robust solution for internal assemblies. On the flip side, external tapered section retaining rings are tailored for installation on shafts. They're the go-to choice for securing components mounted on axles or shafts, ensuring they stay in place even under demanding conditions.

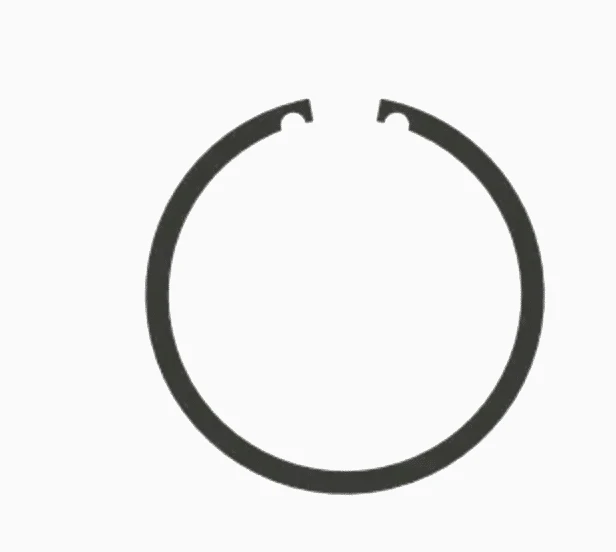

Constant Section Rings

When dealing with heavy-duty machinery or high-impact applications, constant section rings (snap rings) come into play. They feature a uniform radial section, allowing for even load distribution and excellent thrust load capacity. They're the workhorses of the retaining ring world, capable of withstanding significant forces without deformation.

Spiral Retaining Rings

Spiral retaining rings are manufactured by a unique edge-winding process, resulting in a gapless ring with a smooth, burr-free circumference. This process also allows for easy adjustment of ring parameters such as coil diameter, number of turns, and material selection, enabling engineers to tailor the ring to specific application requirements. The clean, unobtrusive design of spiral retaining rings is ideal for applications with tight radial constraints and low to medium thrust load requirements.

Tailoring to Your Needs

While standard retaining rings cover a wide range of applications, some situations call for a more customized approach. This is where our expertise truly shines. Our ability to design and manufacture custom retaining rings ensures that even the most unique or challenging applications can be addressed quickly and effectively.

Material Matters

The choice of material can significantly impact the performance of a retaining ring. Carbon spring steel rings offer high strength at a cost-effective price point, making them a popular choice for many applications. However, in environments where corrosion is a concern, stainless steel rings provide excellent resistance along with good strength properties. For specialized applications, American Ring offers rings in materials like beryllium copper or specific alloy steels, each bringing unique properties to the table. The right material choice can enhance performance, extend lifespan, and ensure compatibility with the overall assembly.

Beyond the Basics: Coatings and Finishes

In many cases, the base material of a retaining ring is just the starting point. Coatings and finishes can enhance corrosion resistance, improve wear characteristics, or simply provide the desired aesthetic. Options like zinc plating, phosphate coating, or black oxide treatment can significantly extend the life of a retaining ring, especially in harsh environments.

Installation Considerations

Even the most perfectly selected retaining ring can fail if not properly installed. Engineers must consider ease of installation and removal, especially in applications where frequent maintenance is expected. We not only provide rings but also offer guidance on proper installation techniques and tools, ensuring that their products perform as intended in real-world applications.

Navigating the Selection Process

Choosing the right retaining ring involves a lot of factors: load requirements, dimensional constraints, environmental conditions, rotation speeds, and budget considerations, to name a few.

Every day our team of engineers helps customers navigate the selection process with ease. Whether it’s calculating thrust loads, considering material compatibility, or designing a custom solution for a unique application, American Ring’s expertise ensures that customers find the right retaining ring for their specific needs.

Our commitment to quality, customization capabilities, and engineering support, that perfect ring is well within reach. Whether you’re working on a standard application or pushing the boundaries of mechanical design, American Ring stands ready to provide the retaining ring solution that will keep your components securely in place, no matter the challenge.

Contact American Ring

For more information on our Constant Section Retaining Rings or to discuss custom specifications, contact American Ring’s team today. We’re committed to providing the solutions you need with precision and expertise.