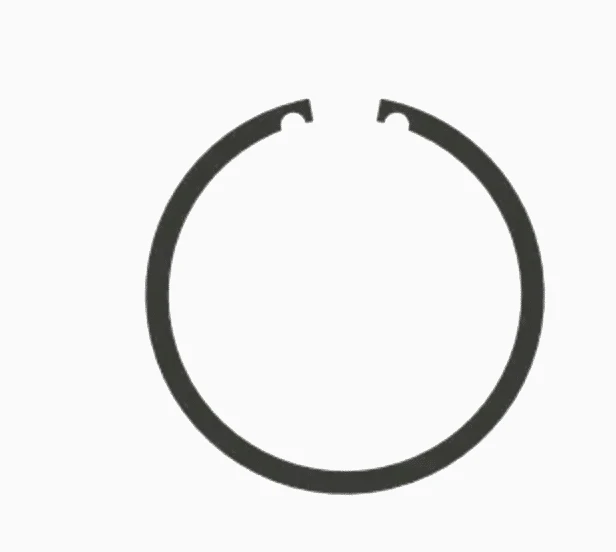

CONSTANT SECTION SNAP RINGS FOR CONSISTENT PERFORMANCE

Why Choose American Ring Constant Section Snap Rings

American Ring’s Constant Section Retaining Rings (Snap Rings) are engineered for reliable performance across a wide range of axial load applications. These rings maintain a uniform cross-section throughout their circumference, offering even stress distribution and high durability in demanding environments. With designs that support both radial and axial retention, constant section rings provide a secure fit without distorting under load, making them ideal for various assemblies across industries.

Uniform Strength

The constant cross-section ensures uniform stress distribution, maximizing load capacity and extending the life of the assembly.

Material Versatility

Available in multiple materials, such as stainless steel, carbon steel, and other alloys, with additional finishes for added corrosion protection.

Wide Size Range

Offered in a comprehensive range of inch and metric sizes to fit various shaft diameters and bore dimensions.

Custom Options Available

We provide customization options to match unique design requirements, ensuring compatibility with specific applications.

Get The F.A.Q.s

This FAQ section aims to answer your most common manufacturing questions about constant section retaining rings and help you understand their capabilities and applications. By addressing these frequently asked questions, American Ring hopes to provide customers with the essential information needed to choose and apply the right ring for their specific requirements.

Constant Section Ring F.A.Q.

Constant section rings are available in various materials, including carbon steel, stainless steel, and sometimes specialty alloys for high-strength or corrosion-resistant applications. The material choice depends on the application’s environmental conditions, such as exposure to moisture, chemicals, or high temperatures.

A constant section ring, also known as a “snap ring” is a type of retaining ring designed to hold components or assemblies onto a shaft or within a bore. The “constant section” design means the ring has a uniform cross-section throughout its shape, providing consistent strength and support along its entire length.

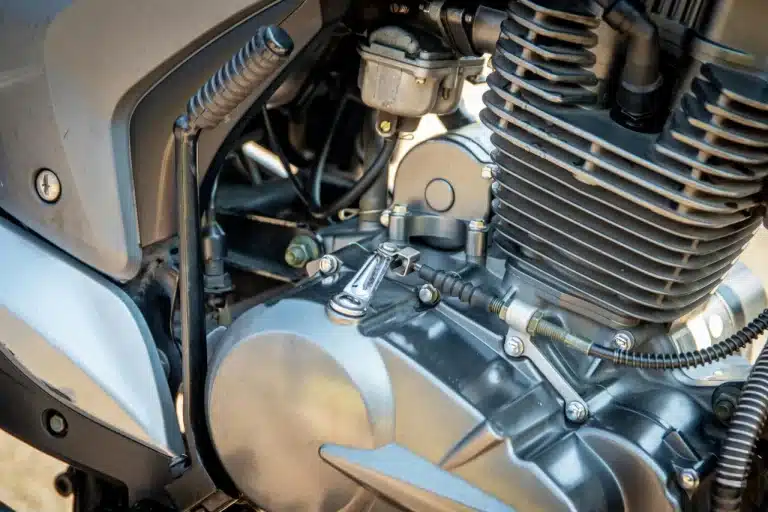

Constant section rings are widely used across industries such as automotive, aerospace, manufacturing, and heavy equipment. They are commonly found in applications like transmissions, engines, pumps, and gear assemblies where reliable, secure retention is critical.

Constant section rings maintain a uniform thickness and width. This even cross-section offers predictable performance and makes them well-suited for applications where uniformity and consistency are essential.

Constant section rings can be installed using snap ring pliers, which compress the ring for placement onto a shaft or within a bore. Removal typically requires a similar process with pliers, which makes maintenance and repairs straightforward.

Yes, American Ring offers customization options for constant section rings, including unique dimensions, materials, and finishes, to meet specific application requirements. Custom designs help ensure that even highly specialized projects have reliable, durable retention solutions.

Industries Served

American Ring’s constant section retaining rings are trusted in industries like automotive, aerospace, and heavy machinery, where consistent performance is a must. These rings are especially effective in applications where a reliable, non-tapered fit is necessary, providing stability under dynamic conditions and repeated use.

Used to keep bearings, shafts, and other rotating components in place, constant section rings ensure stability and help prolong the life of electrical equipment.

In tractors and other machinery, these rings help secure parts in systems that are frequently exposed to vibration, shock, and environmental wear.

Found in heavy-duty equipment like gearboxes, pumps, and motors, where constant section rings maintain alignment and secure fasteners in high-stress environments.

Used in critical components that demand high durability and precision, such as landing gear and control systems, where secure, long-lasting retention is crucial under extreme conditions.

Snap rings are essential in applications like transmissions, axles, and other moving parts that need reliable component retention and can withstand vibration and rotational forces.

Tapered retaining rings are essential in military-grade machinery and vehicles, providing secure fastening of components such as gears, bearings, and shafts. They are designed to endure extreme stress, high-speed operations, and challenging environments.

Contact American Ring

For more information on our Constant Section Retaining Rings or to discuss custom specifications, contact American Ring’s team today. We’re committed to providing the solutions you need with precision and expertise.