Snap Rings Versus Retaining Rings

Differences Between Retaining Rings and Snap Rings

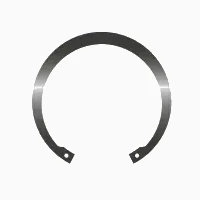

The term “retaining ring” is often used as a catch-all for various types of rings used to secure components to rotating parts. This category includes spiral, beveled, bowed, and interlocking retaining rings, as well as circlips, which usually have “ears” at the open end for easier handling. To add to the confusion, snap rings are sometimes referred to as retaining rings, even though there are clear differences between them.

Snap rings, with their gapped design, can handle high thrust loads but may be overstressed in certain applications. Both retaining rings and snap rings can be designed for external use on a grooved shaft to secure components, or for internal use to retain a bearing within an assembly.

Despite some overlap and confusion in terminology, both types of rings serve distinct roles in component design.

Retaining Rings:

- Used in high-value automotive components as well as drive shafts, electric motors, hydraulic equipment, instrumentation, lighting assemblies, machinery, and in nuclear and aerospace equipment.

- Commonly made from carbon spring steel, stainless steel, or beryllium copper, they are engineered to withstand high stress and pressure, securing critical and expensive machinery.

- Resistant to environments with excessive vibration and are lighter than many alternative fastening solutions such as bolts or screws.

- Provide reliable retention in high-load and high-vibration applications.

Snap Rings:

- As the name suggests, snap rings are designed for quick and easy installation and removal, making them ideal for applications that require frequent assembly and disassembly.

- Commonly used in toys, light-duty equipment, and other applications where ease of installation is important. They can be installed with needle-nose pliers or specialized tools.

- Available in a variety of sizes, shapes, and materials, snap rings are cost-effective and suitable for rapid assembly operations.

- Their lug-free, constant-section design makes them especially useful in applications with limited space or tight clearances.

Both retaining rings and snap rings are cost-effective alternatives to traditional fasteners such as nuts, bolts, screws, and cotter pins, offering significant time and labor savings by eliminating the need for drilling and tapping components.

To learn more about American Ring and the differences between snap rings and retaining rings, call (800) 635-1133 or contact us.